R&D PARTNERSHIP

For nearly 40 years, Top Industrie has put its know-how in the field of high pressure and high temperature, to the service of R&D in various and varied sectors with high technical requirements.The transversal skills and knowledge developed alongside hundreds of researchers, as well as the in-depth knowledge of the industrial world, make Top Industrie the ideal partner for the industrialization of your innovative technologies involving high pressure and high temperature processes.

Over the years, Top Industrie has become a privileged interlocutor in the development of innovative processes, creating a synergy between the academic or institutional research world and the industrial world. Our important involvement in ˝Business development˝ and an efficient partnership with leading laboratories, innovative start-ups, and pioneering players in the industry, allows us to be present on many future projects.

A necessary energy transition

By the end of 2017, the share of renewable energies in the energy mix reached 16%. On July 22, 2015, Parliament passed the law on energy transition for green growth, with a target of 32% of energy consumption in 2030 supplied by renewable energies.The current problem is that these energies are intermittent, unpredictable, produced locally and non-storable, making them difficult to use. Thus, despite France's potential in terms of wind, photovoltaic, tidal, and geothermal energy, it is still dependent on fossil fuels, particularly nuclear power. The "Power to Gas" technology makes it possible to store energy previously transformed into hydrogen by electrolysis of water: thanks to a simple electric current, the water is transformed into hydrogen gas. The hydrogen produced can be used on site, injected into existing natural gas networks (distribution or transport) as is, or converted into synthetic methane after a methanation step, by combining it with CO2.

Hydrogen is colorless, odourless, and non-toxic. It is also very energy efficient with a yield of 33 kWh/kg, two and a half times more than natural gas and three times more than diesel. Another advantage is that it emits no greenhouse gases, no pollutants, and no particles.

Hydrogen can therefore serve the objectives that France has set for the development of renewable energies and the reduction of greenhouse gas emissions and pollutants. Therefore, the Government is seeking to introduce 10% of decarbonated hydrogen into industrial hydrogen by 2023 and between 20% and 40% by 2028.

ADEME's mission is to support projects and territories to promote hydrogen projects from a technical, regulatory, or financial point of view. The government plans to mobilize €100M to finance experiments and initial deployments (investment aid and aid for end uses).

The renewable gas produced in this way meets two essential challenges for a successful energy transition: replacing fossil gas with renewable energies and reusing captured CO2.

Achievements and ongoing projects

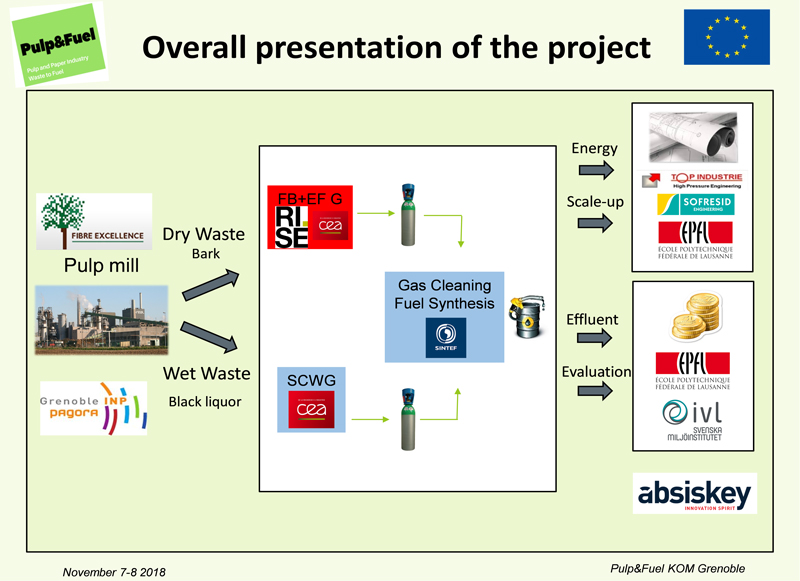

The Pulp&Fuel project involves the thermochemical conversion of industrial waste produced in a pulp and paper mill into biofuels. The project will show that this is possible without having a negative impact on the existing pulp mill operations. The project has chosen to demonstrate its application to the pulp industry that has both dry and wet waste. The concept and technologies can also be applied to other industries, such as municipal waste collection and treatment and the food industry.The technologies implemented in the Pulp&Fuel project are dry and wet gasification and Fischer-Tropsch (FT) fuel synthesis. Dry gasification, such as a fixed bed or an entrained flow reactor, produces a gas rich in hydrogen and carbon monoxide. Wet gasification, in supercritical water, produces a gas rich in hydrogen, carbon dioxide and methane.

Pulp&Fuel will benefit from the synergy between dry gasification and wet gasification in supercritical water. The gasification technologies studied are :

- Fixed bed gasification which is robust and inexpensive and capable of producing synthesis gas of sufficient quality for FT synthesis.

- An entrained-flow gasifier, which is more complex but known for the quality of gas produced.

- Supercritical water gasification for black liquor and paper mill sludge. This technology allows the separation of inorganic species and maximum hydrogen production.

Fuel synthesis by Fischer-Tropsch synthesis has been known for a century, but it is possible to optimize it with different catalysts and reactors to optimize the performance for a given situation.

The integration of the different technologies in a pulp process is the objective of the project. The pulp process has high energy requirements, high pressure steam in the digester and low-pressure steam in the dryer. The FT gasification and synthesis process is globally exothermic and produces thermal energy. The optimization and energy integration of the two processes allows the identification of an optimal synergy between pulp production and fuel synthesis.

Within the framework of this project, as a specialist in high-temperature and high-pressure processes, Top Industrie assists the authorities in the design.

SOLARVI Project

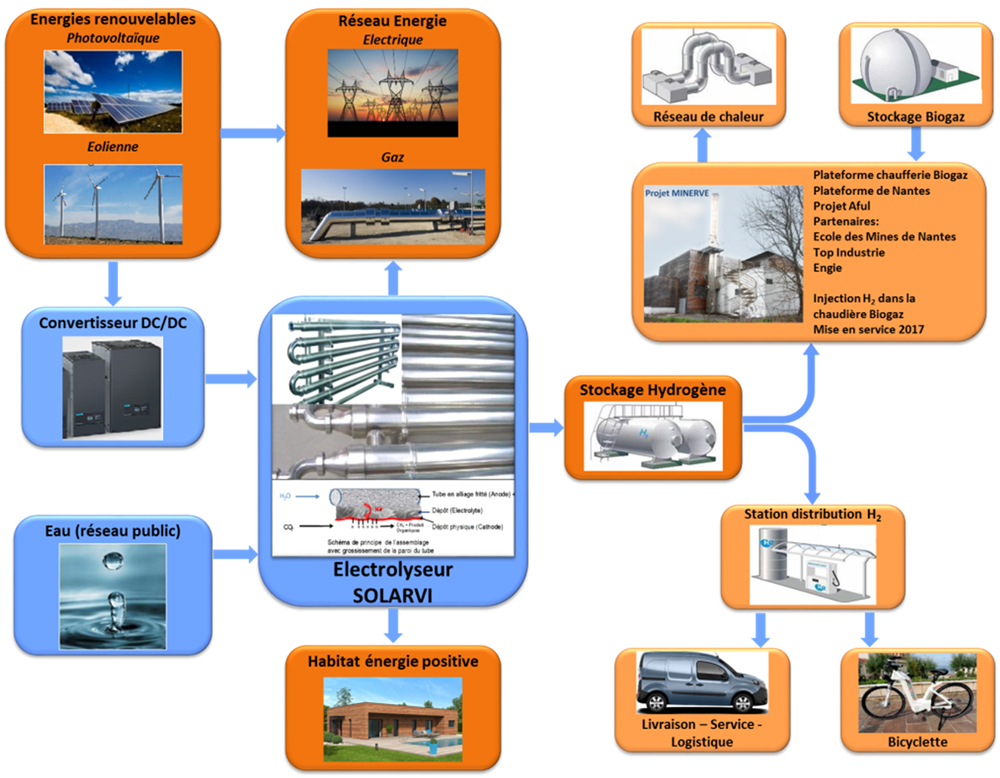

The SOLARVI project seeks to develop an integrated process that allows CO2 to be directly hydrogenated in a high pressure and high temperature electrolyser (290°C and 80 bar), to transform it into chemical products (methane, carboxylic compounds (alcohols or other), almost instantaneously after the in-situ production of hydrogen.Within the framework of the energy transition, the SOLARVI program has several objectives:

- To store the electricity produced by solar energy in chemical compounds, whether hydrogen from the electrolysis of water or the products of CO2 transformation.

- Valorize CO2 waste from biomass in the form of methane, and marketable carbon products as well as hydrogen from electrolysis for green mobility

- Develop French industry by promoting viticulture, agriculture (sugar industry: beet, .... and local processes, in Occitania, then extend the solution internationally

- Fight against the greenhouse effect for the improvement of the climate, focusing on the recovery and treatment of CO2 from the wine industry (fermentation or combustion) and methanization processes by electrolytic hydrogenation, without forgetting green mobility with the use of hydrogen

To meet these challenges, the program aims to develop an integrated solution with the development of a modular, flexible electrolyser capable of producing hydrogen and transforming CO2 into chemicals (methane or alcohols) equipped with a system for compressing CO2 from biomass (methanizer for the wine sector). and a high-power DC/DC converter.

Origin of the project

The project was issued by Béatrice Sala, following a long experience in the field of materials for energy, with her company éMa located at the IES (Institute of Electrolyte and Systems) within the University of Montpellier) which was created to meet the climate and energy challenge.It has been the subject of a patent that Occitania helped in the framework of a prior art research. This patent is registered in Europe and is in the process of being extended to the USA and India.

Solarvi project added value :

- Platinum-free technology

- Moderate operating conditions

- Renewable energies storage

- CO2 treatment

- High selectivity in the choice of transformation products

- Multiple applications

They trus us